Benefits of Using Dried Egg Granules in Cooking

Dried egg granules offer a myriad of advantages for both home cooks and commercial kitchens. Let's delve into some of the key benefits:

Extended Shelf Life

One of the most significant advantages of dried egg granules is their impressive shelf life. When stored properly in a cool, dry place, these granules can last up to 10 years without refrigeration. This longevity makes them an excellent choice for emergency food supplies, camping trips, or long-term storage in commercial kitchens.

Convenience and Versatility

Dried egg granules are incredibly convenient to use. They eliminate the need for cracking and separating eggs, saving valuable time in busy kitchens. These granules can be easily reconstituted with water to create whole eggs, egg whites, or yolks, depending on the specific product. This versatility allows for precise portioning and reduces waste compared to fresh eggs.

Nutritional Value

Despite the drying process, egg granules retain much of the nutritional value found in fresh eggs. They are an excellent source of high-quality protein, essential amino acids, and various vitamins and minerals. This makes them a valuable ingredient for those looking to boost the nutritional content of their meals without compromising on convenience.

Cost-Effective Solution

For commercial kitchens and food manufacturers, dried egg granules can be a cost-effective alternative to fresh eggs. They eliminate concerns about spoilage and reduce the need for refrigerated storage space. Additionally, their long shelf life means less frequent reordering and lower overall inventory costs.

Consistency in Recipes

Dried egg granules provide consistent results in recipes, which is particularly important in commercial baking and food production. Unlike fresh eggs, which can vary in size and composition, egg granules offer a standardized product that ensures reliable outcomes in large-scale food preparation.

How Dried Egg Granules Differ from Powdered Eggs?

While dried egg granules and powdered eggs are both dehydrated egg products, they have distinct characteristics that set them apart:

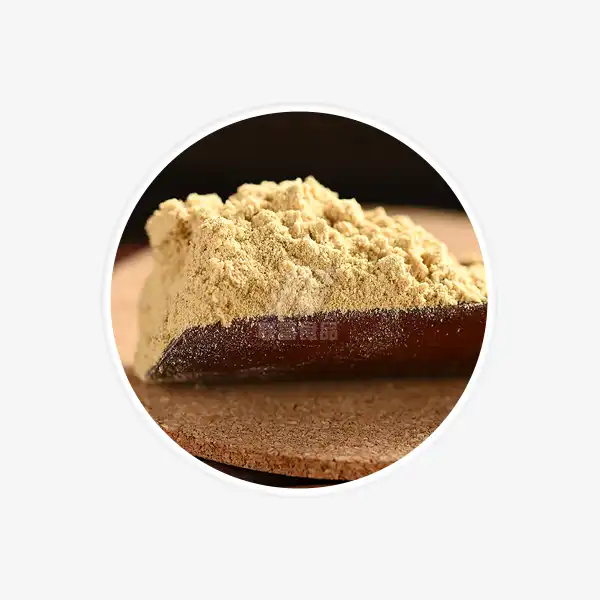

Texture and Appearance

The most noticeable difference between dried egg granules and powdered eggs lies in their texture and appearance. Dried egg granules have a coarser, more granular texture, resembling small pellets or grains. On the other hand, powdered eggs have a fine, dusty consistency similar to flour or other powdered ingredients.

Rehydration Process

The rehydration process for these two products differs slightly. Dried egg granules typically require a bit more time to fully rehydrate, as the water needs to penetrate the larger granules. Powdered eggs, due to their fine texture, tend to rehydrate more quickly and easily. However, both products generally reconstitute well when mixed with the appropriate amount of water.

Culinary Applications

While both dried egg granules and powdered eggs can be used in a wide range of recipes, their unique textures may make them more suitable for different applications. Dried egg granules are often preferred in recipes where a slightly more textured egg product is desired, such as in scrambled eggs or omelets. Powdered eggs, with their finer consistency, may be more suitable for baking applications where a smoother texture is required.

Storage and Handling

Due to their granular nature, dried egg granules may be easier to measure and handle compared to powdered eggs. The granules are less likely to create dust or clump together, making them potentially more convenient for certain kitchen environments. However, both products require proper storage in airtight containers to maintain their quality and prevent moisture absorption.

Production Process

The production processes for dried egg granules and powdered eggs differ slightly. Dried egg granules are typically produced through a spray-drying process that creates small, uniform granules. Powdered eggs are often made using a similar spray-drying technique, but with additional processing to achieve a finer powder consistency. These differences in production can affect the final texture and rehydration properties of the products.

Common Uses for Dried Egg Granules Explained

Dried egg granules are incredibly versatile and can be used in a wide array of culinary applications. Let's explore some of the most common uses:

Baking and Pastry

In the world of baking, dried egg granules shine as a convenient and reliable ingredient. They can be used in cakes, cookies, muffins, and bread recipes, providing the binding and leavening properties of fresh eggs. For pastry chefs, egg granules offer consistency in recipes that require precise measurements, such as custards, meringues, and soufflés.

Breakfast Dishes

Dried egg granules are an excellent option for creating quick and easy breakfast dishes. They can be reconstituted and used to make scrambled eggs, omelets, or frittatas. The granules are particularly useful for camping trips or outdoor cooking where fresh eggs might be impractical to transport and store.

Meat Products and Binding Agents

In the meat industry, dried egg granules serve as effective binding agents in products like meatballs, sausages, and patties. They help improve texture, moisture retention, and overall product quality. The granules can also be used as a coating for breaded meats, providing excellent adhesion and a crispy texture when fried.

Sauces and Dressings

Egg granules can be incorporated into various sauces and dressings, such as mayonnaise, hollandaise, and Caesar dressing. They provide the emulsifying properties needed to create smooth, stable sauces without the risk of bacterial contamination associated with raw eggs.

Nutritional Supplements

Due to their high protein content and long shelf life, dried egg granules are sometimes used in nutritional supplements and protein powders. They can be easily blended into smoothies or protein shakes, providing a boost of essential amino acids and nutrients.

Emergency Food Supplies

The long shelf life of dried egg granules makes them an ideal component of emergency food kits. They provide a reliable source of protein and nutrients that can be stored for extended periods without refrigeration, making them valuable for disaster preparedness and long-term food storage.

Commercial Food Production

In large-scale food manufacturing, dried egg granules offer numerous advantages. They can be easily incorporated into dry mixes for products like cake mixes, pancake batters, and instant noodles. The granules' consistent quality and extended shelf life make them particularly valuable for products that require long-term storage or distribution.

Specialty Diets

For individuals following specific diets, such as low-carb or high-protein regimens, dried egg granules can be a convenient way to increase protein intake. They can be easily added to various dishes without significantly altering the carbohydrate content, making them popular among athletes and health-conscious consumers.

Pet Food Industry

Dried egg granules are also utilized in the pet food industry, particularly in premium dog and cat foods. They serve as an excellent source of high-quality protein and essential nutrients, contributing to the overall nutritional profile of pet food products.

Institutional Cooking

In institutional settings such as schools, hospitals, and military facilities, dried egg granules offer a practical solution for large-scale meal preparation. They eliminate the need for cracking and handling large quantities of fresh eggs, reducing labor costs and minimizing food safety risks associated with raw egg handling.

Conclusion

Dried egg granules and powdered eggs each have their unique characteristics and applications in the culinary world. While they share many similarities, the granular texture of dried egg granules can provide certain advantages in handling and specific recipes. Both products offer extended shelf life, convenience, and versatility, making them valuable ingredients for home cooks and food industry professionals alike.

For those interested in exploring the world of dehydrated egg products and other innovative food ingredients, Xinghua Lianfu Food Co., Ltd. offers a wide range of high-quality options. With over two decades of experience in dehydrated food production, Lianfu Food is committed to providing top-notch products that meet international quality standards. To learn more about our dried egg granules and other dehydrated vegetable products, please contact us at qingzhengliu@jslianfu.com.

_1729843393550.webp)