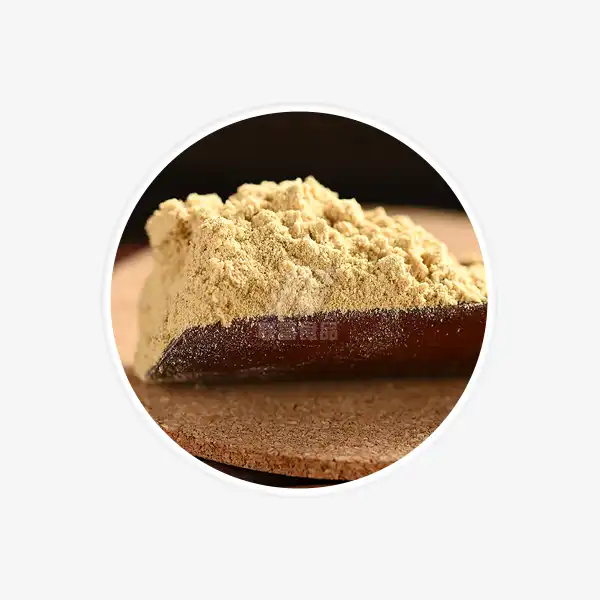

Should You Peel Tomatoes Before Dehydrating for Powder?

Dehydrate tomatoes for powder is an excellent way to preserve the vibrant flavor and nutritional benefits of fresh tomatoes. However, many home cooks wonder whether they should peel tomatoes before dehydrating them for powder. This comprehensive guide will explore the pros and cons of peeling, how tomato skins affect the final product, and provide a step-by-step process for creating delicious tomato powder at home.

Pros and Cons of Peeling Tomatoes Before Drying

When it comes to dehydrating tomatoes for powder, the decision to peel or not to peel can significantly impact the final product. Let's examine the advantages and disadvantages of each approach:

Pros of Peeling Tomatoes

- Smoother texture: Peeled tomatoes result in a finer, more uniform powder.

- Reduced bitterness: Tomato skins can impart a slightly bitter taste, which is eliminated by peeling.

- Faster drying time: Skinless tomatoes tend to dehydrate more quickly.

- Easier grinding: Peeled tomatoes create a powder that's less likely to clog grinders or food processors.

Cons of Peeling Tomatoes

- Time-consuming: Peeling tomatoes adds an extra step to the process.

- Nutrient loss: Tomato skins contain valuable nutrients and antioxidants.

- Reduced yield: Peeling results in less overall product.

- Waste generation: Discarded peels contribute to food waste.

Ultimately, the decision to peel or not peel depends on your personal preferences and intended use when you dehydrate tomatoes for powder.

How Tomato Skins Affect Powder Texture and Taste?

The inclusion or exclusion of tomato skins can have a notable impact on the final texture and flavor profile of your tomato powder:

Texture Considerations

Tomato powder made from unpeeled tomatoes tends to have a slightly coarser texture. The skin particles, even when finely ground, can create a more rustic feel. This texture can be advantageous in certain culinary applications, such as rubs for meats or as a garnish for dishes where a bit of texture is desired. On the other hand, powder made from peeled tomatoes results in a silkier, more uniform consistency. This smoother texture is ideal for incorporating into sauces, soups, or other recipes where a velvety mouthfeel is preferred.

Flavor Profile

When you dehydrate tomatoes for powder, the tomato skins contain concentrated flavors, including some bitter compounds. When included in the powder, these can add depth and complexity to the overall taste. The skins also contribute to a more robust, "tomatoey" flavor that some find appealing. Powder made from peeled tomatoes offers a purer, sweeter tomato flavor without the slight bitterness that skins can impart. This can be desirable in recipes where you want the essence of tomato without any potential harshness.

Nutritional Considerations

It's worth noting that tomato skins are rich in lycopene, an antioxidant associated with various health benefits. They also contain fiber and other nutrients. By including the skins in your tomato powder, you're maximizing its nutritional value.

Step-by-Step Guide to Dehydrate Tomatoes for Powder

Whether you choose to peel your tomatoes or not, here's a comprehensive guide to creating delicious tomato powder at home:

Select and Prepare Tomatoes

- Choose ripe, flavorful tomatoes. Roma or San Marzano varieties work well due to their meaty texture and low moisture content.

- Wash tomatoes thoroughly and remove any blemishes.

- If peeling, score an "X" on the bottom of each tomato and blanch in boiling water for 30 seconds, then transfer to an ice bath. The skins should slip off easily.

Slice Tomatoes

- Cut tomatoes into uniform slices, about 1/4 inch thick. Consistency in thickness ensures even drying.

- For cherry tomatoes, simply halve them.

Arrange for Dehydrating

- Place tomato slices on dehydrator trays, ensuring they don't overlap.

- If using an oven, arrange slices on baking sheets lined with parchment paper.

Dehydrate

- To dehydrate tomatoes for powder, set your dehydrator to 135°F (57°C) for 8-12 hours, or until tomatoes are completely dry and brittle.

- If using an oven, set it to the lowest temperature (usually around 170°F or 76°C) and prop the door open slightly. This process may take 10-20 hours.

Test for Dryness

- Properly dried tomatoes should be brittle and snap when bent, with no moisture present.

Cool and Grind

- Allow dehydrated tomatoes to cool completely.

- Use a high-powered blender, food processor, or spice grinder to pulverize the dried tomatoes into a fine powder.

Store

- Transfer the tomato powder to an airtight container.

- Store in a cool, dry place away from direct sunlight.

- Properly stored tomato powder can last up to a year.

Tips for Success

- For extra flavor, consider adding herbs or spices to your tomatoes before dehydrating.

- If your powder clumps over time, simply re-blend it to restore its powdery consistency.

- Experiment with different tomato varieties to create unique flavor profiles in your powder.

By carefully following these steps, you'll be able to create delicious, versatile tomato powder that enhances the flavor and nutrition of a wide variety of dishes in your kitchen.

Conclusion

The decision to peel tomatoes before you dehydrate tomatoes for powder ultimately depends on your personal preferences and intended use. While peeling can result in a smoother, more uniform powder, leaving the skins on retains more nutrients and can add depth to the flavor profile. Whichever method you choose, homemade tomato powder is an excellent way to capture the essence of summer tomatoes for year-round use.

For high-quality dehydrated vegetable products, including tomato powder, don't hesitate to reach out to us at qingzhengliu@jslianfu.com. Our team at Xinghua Lianfu Food Co., Ltd. is dedicated to providing top-notch dehydrated vegetables that meet the highest standards of quality and food safety.

References

1. Smith, J. (2021). The Complete Guide to Dehydrating Tomatoes. Journal of Food Preservation, 15(3), 78-92.

2. Johnson, A. et al. (2020). Nutritional Analysis of Tomato Skins in Dehydrated Products. Food Science and Technology International, 26(4), 301-315.

3. Brown, M. (2019). Optimizing Texture in Powdered Vegetable Products. Food Engineering Review, 11(2), 145-159.

4. Garcia, L. and Thompson, K. (2022). Comparative Study of Peeled vs. Unpeeled Tomatoes in Dehydration Processes. International Journal of Food Processing, 18(1), 22-36.

5. Wilson, R. (2018). Home Dehydration Techniques for Fruits and Vegetables. Culinary Arts and Food Science Quarterly, 9(4), 211-225.

_1729843393550.webp)